SPP Pumps operates R&D, manufacturing, test facilities and service sites in the UK, USA, India, France, South Africa, Dubai and Egypt, and local sales offices in Norway, Singapore, Italy, Poland, Holland and the Czech Republic.

All SPP Pumps sites are ISO9001:2008, ISO14001:2004 and OHSAS 18001:2007 approved. The company also has ISO/TS 29001 Certification, the quality management system (QMS) requirement for companies supplying to International Petroleum, Petrochemical and Natural Gas Industries.

Over 500 staff, including 50 specialist engineers, provide round-the-clock advice and support for performance-critical pumping operations, for some of the world’s largest organisations.

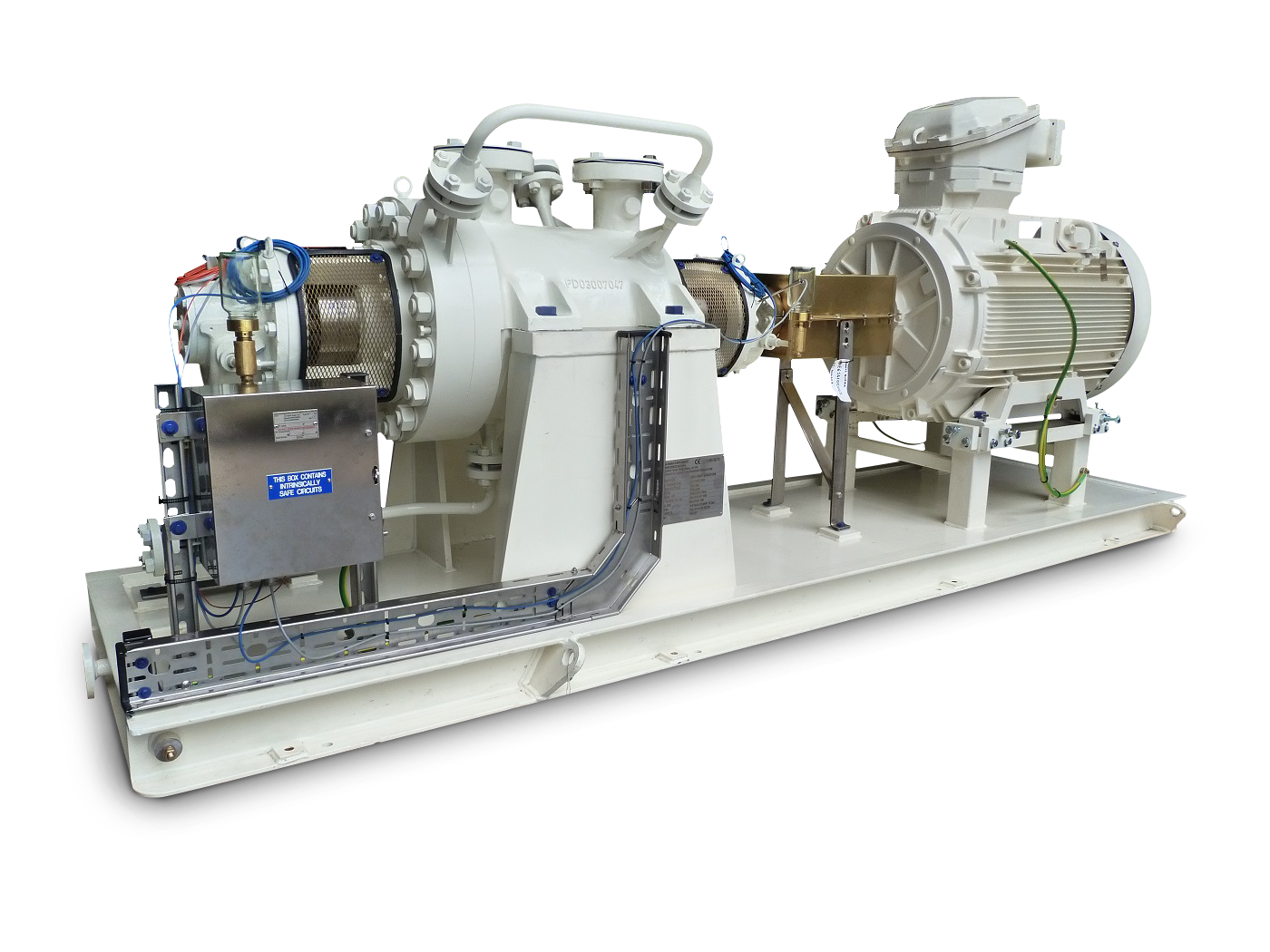

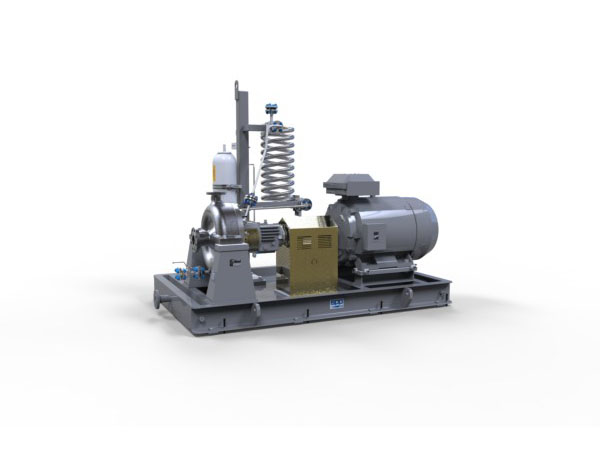

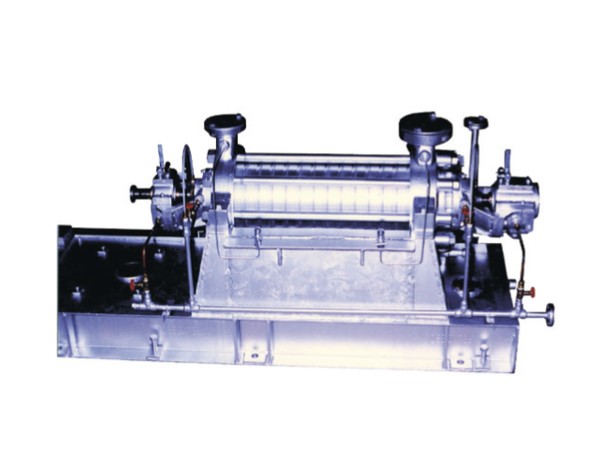

PROVEN DESIGN FEATURES FOR SUPERIOR PERFORMANCE AND ENDURANCE.

Offering performance features specifically engineered for the rigours of petrochemical Oil & Gas applications, SPP Pumps’ API 610 latest edition pump range sets the standard for fully compliant design…

- Pump design life exceeds API 610 requirements

- Casing thickness can be designed to exceed API for enhanced life

- Bearing design life exceeds API standards, assured to at least 40,000 hours with continuous operation at rated condition

- Bearing housings equipped with high quality bearing isolators and magnetic drain plugs to prevent contamination

- Pumps designed with Stable head / flow characteristics

- Close radial running clearances between case and impeller wear rings for increased efficiency

- All radially split case pumps have metal to metal fit with confined controlled compression gaskets

- Shaft deflection at mechanical seal is below .002 mm under the most severe operating conditions thus improving seal reliability

- API 682 seal and seal systems ensure extended uninterrupted service life

- Condition monitoring options available

- Flexible Engineering team to accommodate client specific design requirements