Global support

We recognise that lives, properties and livelihoods

can depend on a pump’s performance.

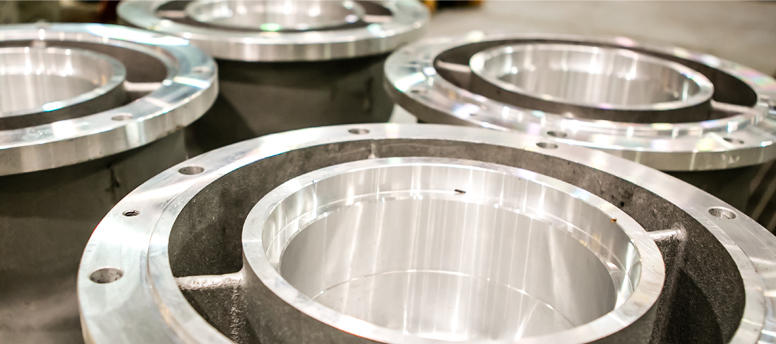

At SPP Pumps we are committed to providing the very best in customer service support, it's what we pride ourselves upon. Our genuine spare parts, pump engineering and pump testing services will ensure that every pump we supply maintains the highest standards in order to reduce customer downtime.

Pressure testing transformer oil pump cases using air and water is just the start. Every SPP transformer pump that is built is also performance tested. The system is then pressure tested for 24 hours on a warm oil test rig using transformer oil at 60°C.

Each individual pump's performance is recorded and detailed on a Quality Assurance certificate shipped with the unit. Customers are welcome to observe their pumps during performance testing.

In fire protection there is no room for shortfalls in the processes, procedures or attitudes affecting maintenance and the ability of a system to do its job as needed. There is a need to keep an eye on the fire pump at all times, not only when periodically tested.

The true cost of a fire to a business cannot be measured easily or ever fully recovered. Loss of life, customer disruption, health and safety intervention, criminal and insurance investigations and insurance premium escalation are just a few of the possible risks associated with inadequate fire protection. SPP Pumps, through the maintenance and servicing of fire protection equipment, reduce this risk. As the world leader in the manufacture of Listed and Approved fire pump packages, SPP Pumps is the first choice for the service and maintenance of your fire protection pump sets.

SPP Pumps offers a variety of fire pump service packages designed to ensure that your fire protection system is fully functional and working perfectly for when you need it most. Each package can either be on a 6 or 12 monthly contract and all cover electric and diesel driven fire pumps.

Contact Us

SPP Pumps operate a network of strategically based pump service engineers who are dedicated to providing a rapid response to customer needs. SPP engineers are the best in the business at handling a variety of tasks ranging from routine maintenance and emergency breakdowns, through to full installation and commissioning of various pump packages, regardless of make or model.

All SPP Pumps engineers undergo stringent training programmes including; safety passports, confined space, first aid and core mechanical and electrical engineering updates. All of these core training areas are what differentiates our experienced pump maintenance and repair specialists from the industry, resulting in a renowned engineering service to all customers.

SPP Pumps field service engineers travel the world in the support of SPP Pumps engineered products. Suitably qualified in all Health & Safety aspects with extensive experience working on both land-based projects and offshore located oil & gas installations. Be it installing, commissioning, testing or remedial tasks, SPP Pumps engineers can be mobilised within a few hours.

Known as a world leader in onshore and offshore applications, SPP Pumps have the expertise to suitably provide high-quality oil and gas pump applications worldwide. Well supported by factory-based design engineers and head office administration and coordination, SPP Pumps provide an unequalled level of customer service and support.

We provide expert and high-quality pump valve repair for all types, sizes and makes of valves from a wide range of manufacturers.

In order to minimise the ownership costs of capital equipment, it is critical for the user to monitor and maintain the water pump equipment once installed. Failure to do so will impact both on the mechanical integrity and economic performance of the pump system installed.

Early diagnosis of potential industrial water pump equipment failure can result in considerable repair cost savings and crucially a reduction in unplanned downtime. Monitoring of pump energy consumption and system efficiency will bring visibility to pump wear, operating efficiency and highlight any system irregularities, all of which will help the user minimise energy consumption and reduce operating costs.

The SPP condition monitoring water pump systems can provide this level of security by detecting, analysing and evaluating key equipment performance:

| Performance/Efficiency degradation | Driver alignment condition |

| Bearing vibration levels | Residual unbalance |

| Bearing operating temperatures | Cavitation |

| Driver alignment condition |