A Leading Oil Pump Manufacturer

SPP Pumps is a world leader in the design and manufacture of pumping equipment for both onshore and offshore applications. In-house expertise ensures compliance with all applicable specifications and regulations. This reputation has been built up since 1970 when SPP pumps on the Argyll platform delivered the very first North Sea oil to come ashore. Since then, experience in the North Sea has allowed SPP Pumps to supply equipment to the most extreme environments around the world.

SPP Pumps was the first company to obtain the ISO/TS 29001 Certification, which defines quality management system (QMS) requirements for product and service supply organisations to International Petroleum, Petrochemical and Natural Gas Industries.

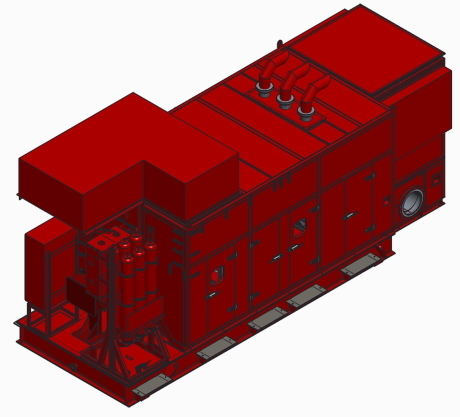

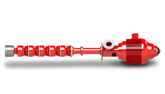

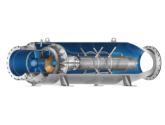

Offshore and Onshore Pump Solutions

When it comes to the production of oil and gas, the industry responsible is faced with a number of obstacles and exposures; requiring unique pumping solutions and expertise. SPP Pumps have facilitated and worked alongside the oil and gas sector for over 140 years and its undeniable success has proven quality pump engineering to this day.

SPP Pumps’ products are exclusively designed and configured, based on the specific requirements of individual cases; the client may have a small footprint to work with, yet high-temperature fluids, therefore could require a vertical turbine pump. On the other hand, SPP Pumps’ API range could suitably provide for a client who has minimal access after application, due to the pump’s reduced maintenance requirements. As a renowned oil and gas pump manufacturer, we offer a wide range of systems with varied options of design configurations catered for their specific use and application.

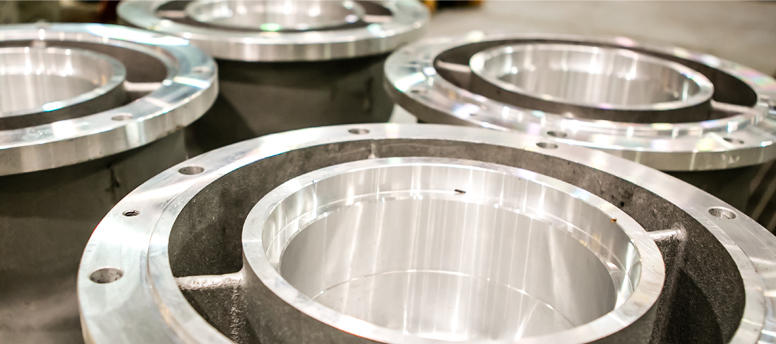

Oil and Gas Pump Valve Repair Specialists

As a leading pump manufacturer, we pride ourselves on providing the whole package to our clients from initial pump design and consultation through to application and comprehensive repair. Our years of experience in many industrial field is what sets us as apart from the competition. With pump service engineers on hand at our strategically located UK service centres; you can be sure of the best customer service in the field when you need it most.

In an exposed environment such as oil and gas, unique and robust pump solutions are required. This where our oil and gas valve repair service is of utmost importance. With the sheer demands required by this industry, pumps and their associated systems are put to their absolute limit but with SPP Pumps at hand, you have the peace of mind that systems work at optimum performance all–year-round.

SPP Pumps Around the World

SPP Pumps has supplied pumping equipment to many of the major international oil companies for a variety of applications from Azerbaijan to Zimbabwe. We boast over 850 SPP Pumps systems applied within more than 140 fields and 700 installations. As an expert gas and oil pump manufacturer, with global recognition for our project management and solving customer application challenges, SPP Pumps delivers critical installations for where it matters.

For help with your next pump application, talk to the experts.

Your Local Contact

SPP Pumps, Inc.

2905 Pacific Drive, Norcross, GA 30071, U.S.A.

Tel: +1 (770) 409 3280

Fax: +1 (770) 409 3290

Email: john_kahren@spppumps.com